Steel sheets generally range in thickness from 1/16 inch to 3/16 inch, while steel plates include thicker products varying from 3/16 inch to numerous inches thick. Recognizing the properties, types, and applications of steel sheets and plates is essential for engineers, engineers, and suppliers that depend on these products for their tasks.

One of the most typical types of steel sheets is hot-rolled steel, which is produced by rolling steel at high temperature levels, making it less complicated to form and form. In addition, there are specialized steel sheets, such as galvanized steel, coated with a layer of zinc to provide boosted rust resistance, making it suitable for exterior applications, consisting of roof and siding.

Steel plates come in various qualities, including architectural, marine, and abrasion-resistant, each with certain residential or commercial properties customized for different settings and tons. The selection of the proper grade and kind of steel sheet or plate is essential for making certain the safety, efficiency, and longevity of the last product.

The manufacturing of steel sheets and plates includes substantial processes consisting of reducing, flexing, welding, and finishing. Welding is one more crucial process in the assembly of steel frameworks, calling for knowledge of different welding methods such as MIG, TIG, and stick welding. The ending up procedure may include surface treatments and finishings that boost the material's resistance to rust, enhance appearances, and prolong service life.

The usage of steel sheets and plates has actually advanced with advances in technology, leading to innovations such as high-strength low-alloy steels, which provide equivalent mechanical properties to standard qualities while minimizing weight. The regular research study and advancement in the metallurgy of steel are focused on creating lighter, more powerful, and extra corrosion-resistant products, which will certainly additionally broaden the adaptability and applications of steel sheets and plates in different markets.

Sustainability is a progressively essential consideration in the production and use steel sheets and plates. Steel recycling has actually been an indispensable component of the sector for years, and most of brand-new steel created comes from recycled materials. This procedure dramatically reduces the carbon impact connected with steel production, aiding to resolve ecological issues. Producers are taking actions to enhance their processes, lowering waste and power consumption, straightening with worldwide sustainability goals. The capacity to create premium steel while minimizing ecological effect not only profits the planet yet likewise enhances the track record of companies devoted to lasting techniques.

The building and construction market greatly depends on steel sheets and plates for creating durable frameworks that can stand up to diverse ecological forces. In architectural applications, the strength-to-weight ratio of steel permits for slim designs that do not jeopardize on safety or capability. Steel plates work as essential elements in bridge construction, with designers designing steel plate girders to sustain hefty loads and period cross countries. In addition, steel sheets are extensively utilized in erecting steel structures, supplying flexibility in style while ensuring conformity with building ordinance and security standards. The building of high-rises and large commercial sheds exemplifies the synergetic connection in between steel sheets and plates and contemporary building practices.

In the manufacturing field, steel sheets and plates form the foundation of a significant variety of items. From home appliances to autos, the demand for trusted and long lasting materials is vital. Automotive manufacturers use high-strength steel sheets to generate body panels that are light-weight yet exceptionally sturdy, which adds to enhanced gas performance without sacrificing security. The appliance market advantages from cold-rolled sheets with boosted surface finishes, guaranteeing visual allure while providing lasting sturdiness versus day-to-day wear and tear. The assimilation of steel sheets in equipment and machinery not only improves the performance of items yet additionally extends their lifecycle, offering significant worth to suppliers and customers alike.

On a read more much more specific note, the oil and gas sector's need for steel plates is driven by the building and construction of pipes and storage space facilities that must endure extreme environments and pressures. The demands for these products determine that they have high resistance to both rust and mechanical anxiety. Steel plates made use of in these applications are usually made to exacting criteria, guaranteeing they can hold up against the roughness of transport and storage space of varied materials, consisting of unrefined oil and all-natural gas. In addition, overseas boring systems are bordered by extreme aquatic problems, demanding using marine-grade steel plates that ensure structural integrity and safety.

Beyond commercial applications, the visual use of steel sheets has actually discovered a home in architectural design. Modern style welcomes modern technology and advancement, integrating steel sheets not only for structural honesty yet for aesthetic effect. Steel can be manipulated to develop vibrant facades, roofing, and indoor layout aspects that celebrate the material's industrial heritage while supplying modern aesthetic appeals. The use of corten steel, known for its rustic patina, is specifically prominent in creating exterior sculptures and developing facades that mix into natural environments, showcasing the flexibility and elegance of steel in different style philosophies.

A number of factors have to be thought about to ensure your tasks proceed efficiently when it comes to choosing distributors for steel sheets and plates. The credibility of the distributor, product array, high quality assurance procedures, lead times, and consumer service are essential components in selecting a companion. Many producers also need specific accreditations, such as ISO 9001, to ensure that vendors fulfill worldwide top quality management criteria. The accessibility of value-added solutions, such as pre-fabrication and machining, can improve task timelines, offering added value to suppliers and contractors.

As we look toward the future, the role of steel sheets and plates will likely pivot in action to arising modern technologies and materials science. The general pattern towards modular construction is likely to further highlight the value of steel sheets and plates, as standard components create effectiveness in setting up and lower on-site construction time.

Finally, steel sheets and plates are necessary products that create the structure for numerous applications across a diverse variety of industries. From their vital function in building and producing to their visual payments to modern-day style, these functional products remain to evolve in response to technological developments and sustainable methods. As industries strive for innovation and environmental responsibility, the importance of understanding and choosing the appropriate steel sheets and plates will remain pivotal to achieving functional, affordable, and sustainable engineering solutions. Whether you are a contractor, producer, or designer , acknowledging the integral role of steel in your tasks will certainly not just boost efficiency however likewise contribute to the resilience and sustainability of our developed atmosphere. As we progress, it is clear that steel sheets and plates will remain to shape the future of design and style in cutting-edge and interesting methods.

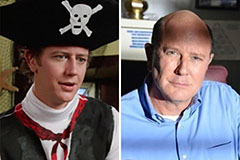

Kirk Cameron Then & Now!

Kirk Cameron Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Batista Then & Now!

Batista Then & Now!